Understanding the advantages of RIP Software for DTG

The importance of digital textile printing has grown significantly throughout the last decade. While the process is challenging and the workflow must be well understood, technological advances in software, printing equipment, print heads and inks, have allowed the creation of more cost-effective solutions for short print runs.

Direct-to-garment [DTG] printing represents a growing segment of this market. This is because of the technology’s ability to customise garments. The basis of DTG production is finished and, in many cases, pre-prepared garments, which can be used for customisation both on a large scale and in small volumes. There are two types of machines on the market: commercial and industrial. Traditionally, the first ones were found in local businesses where very short customisation runs or premium clothes were produced. In contrast, the industrial printers are responsible for larger runs in factories that focus on outsourcing.

Today, a hybrid between the two previous models is emerging and the popularisation of mass customisation, boosted by the growth of ecommerce, is facilitating that. With this model, companies provide users with a production centre in just a few clicks. They will be able to print their own designs on-demand and with no minimum or maximum number of repetitions. It enables companies to be more flexible in responding to both individual orders and larger print runs.

From a supply chain point of view, there is a requirement among print service providers for both machine types, either through synergies or by expanding resources. For this reason, DTG is gaining more and more strength as it allows companies to choose from a wide range of devices which can adapt to the needs of each manufacturer and situation on an individual basis, thus simplifying customisation in the fashion and apparel market.

RIP software for DTG printing

Behind every good DTG print, there is a learning process based on the technology used to create a workflow, how this technology has been adapted to meet the needs of the print service provider, and the requirements of the end consumer. Manufacturer’s must learn about the printers, the inks, the fabrics, and especially the software to enhance results.

RIP software is responsible for interpreting a file and calculating how many drops of each colour will be needed to obtain the best results. It does this while considering the productivity of the printing device.

In other words, if you invest in a DTG printer, whether industrial or desktop, RIP software is the solution to allow manufacturers to get the most out of a printer’s functionalities.

Inèdit always recommends RIP software with modes specifically designed for DTG printing. But which key features should be measured when looking for the right RIP software?

The right software

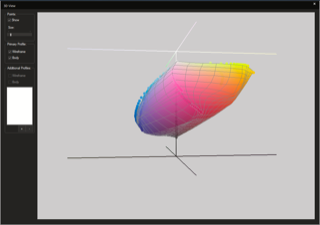

It is important to consider colour management. With RIP software you can operate with CMYK and RGB colour profiles. The difference between the two methods lies in the way they interpret the colours they have. In short, CMYK profiles have four inks and create colours from the superposition of these. White is created from the absence of these colours and black is created from the sum of these colour profiles.

Meanwhile, the RGB method has three inks and creates new colours from the variation of their light. This allows for the interpretation of a wider range of colours. Therefore, a RIP that works in RGB will significantly increase the number of colours that a printer can export, thus improving printing quality.

An RIP software’s calibration system also influences the accuracy of a colour base when printing. Calibration is carried out to understand what colour interpretation capacity a device has, and then indicates how each of the colours and gradients should be exported. An intuitive and fast calibration system is what Inèdit recommends when printing DTG. RIP software should also have integrated concepts to calculate the ink limit, make linearisations, and see the profile of the printer in operation.

Additionally, in discovering the right RIP software, white management must be factored in. The white channel in DTG printing is one of its main features. With the correct white management, it is possible to save money and ink in production runs. In DTG printing, the white channel is used to create a layer between the substrate and the ink when the substrate is black, or a specific colour, so that the colour of the printed ink is not affected by the substrate. The disadvantage of not managing this channel is that the use of white ink increases significantly, thus affecting the price of production. It is therefore important to have a RIP software that has a set of defined standards.

For instance, neoStampa Delta incorporates different printing modes depending on the use of white ink. Printers can choose between creating an all-white background under the drawing, or use default values for black, grey and coloured backgrounds.

Another benefit of the white channel generation is that it allows hybrid DTG printers to detect the white they are going to print first and the colour channels they are going to put on top of it.

However, the settings for black backgrounds should also be understood. The RIP software should allow print service providers to use the black background of a T-shirt, for example, as to avoid using black ink or creating greys by mixing white ink with the same background. By using this type of configuration, up to US$0.60 per print, and up to 30% of white ink consumption, can be saved.

Moreover, RIP software should have a choke system. This is the method that avoids registration problems when printing an image on a background colour. It should also support transparency: accept several formats that use a transparent colour or an alpha channel and take advantage of the T-shirt background.

On-demand printing

DTG print service providers have traditionally provided for end consumers on-demand thanks to growth in ecommerce. However, there is growing trend among leading brands to capitalise on the growing demand for personalised fashion and Web2Print. Some larger brands have been implementing DTG to limited short-run collections based on the latest fashion trends inspired by online influencers and celebrities.

In the industrial field, this translates into the need to generate more agile communication with the customer and faster and more efficient production. Therefore, digital printing continues to grow as it allows for the start and stop of print runs at any time.

Web2Print has been born in response to this new trend. It consists of personalisation at its maximum exponent, allowing a customer, both individuals and businesses, to send a file in a specific format from

a website so that the manufacturer can print it directly, whether it is just one unit or a short print run. But how can RIP software help in this whole process?

Firstly, it maintains the colour output that the customer expects when sending a file and secondly, it helps the manufacturer organise the workflow and extract cost information.

If a customer sends a file with an embedded profile - for instance, Adobe RGB or Apple RGB - it is easy for the manufacturer to access those from their RIP software, as long as it is specialised in RGB. This way, the printed colours will meet expectations because they accurately match what the customer saw on screen when they originally placed the order. This process also reduces the need for sampling.

From a manufacturer's point of view, Inèdit highlights two drawbacks that could be solved with a good RIP software. The first of these is a lack of organisation when receiving work orders and transferring them to production. A very useful concept included in some RIP software is the print queues. These arrange pending work orders into different queues according to the production printer that is going to be used.

In addition, there is some RIP software, like neoStampa, which enables users to access print queues remotely from anywhere in the world: printing sequences can be organised, the preferred output for each machine can be set, and print runs can be stopped and resumed at any time. All of this can be dictated from outside the manufacturing facility and simplifies the flow of communication from any department anywhere in the world.

Furthermore, it is important that the software incorporates a cost control screen. This is how manufacturers put a price on orders placed online or remotely. A cost control system will consider both the productivity of a company and the costs derived from it. Therefore, by knowing the units needed for each run, the current ink price, and the cost of consumables, basic production costs can be generated. That helps manufacturers apply a final price to the printed product.

[sub-head] neoStampa Delta for DTG

For years, Inèdit has been working with leading DTG printing brands such as SanRoq, Epson and Brother but this year has taken a further step by launching a new version of neoStampa Delta which is equipped with a module dedicated to the high-growth digital DTG printing market. The latest software upgrade is designed to work with both small- and large-format printers.